Implant software

Implant software

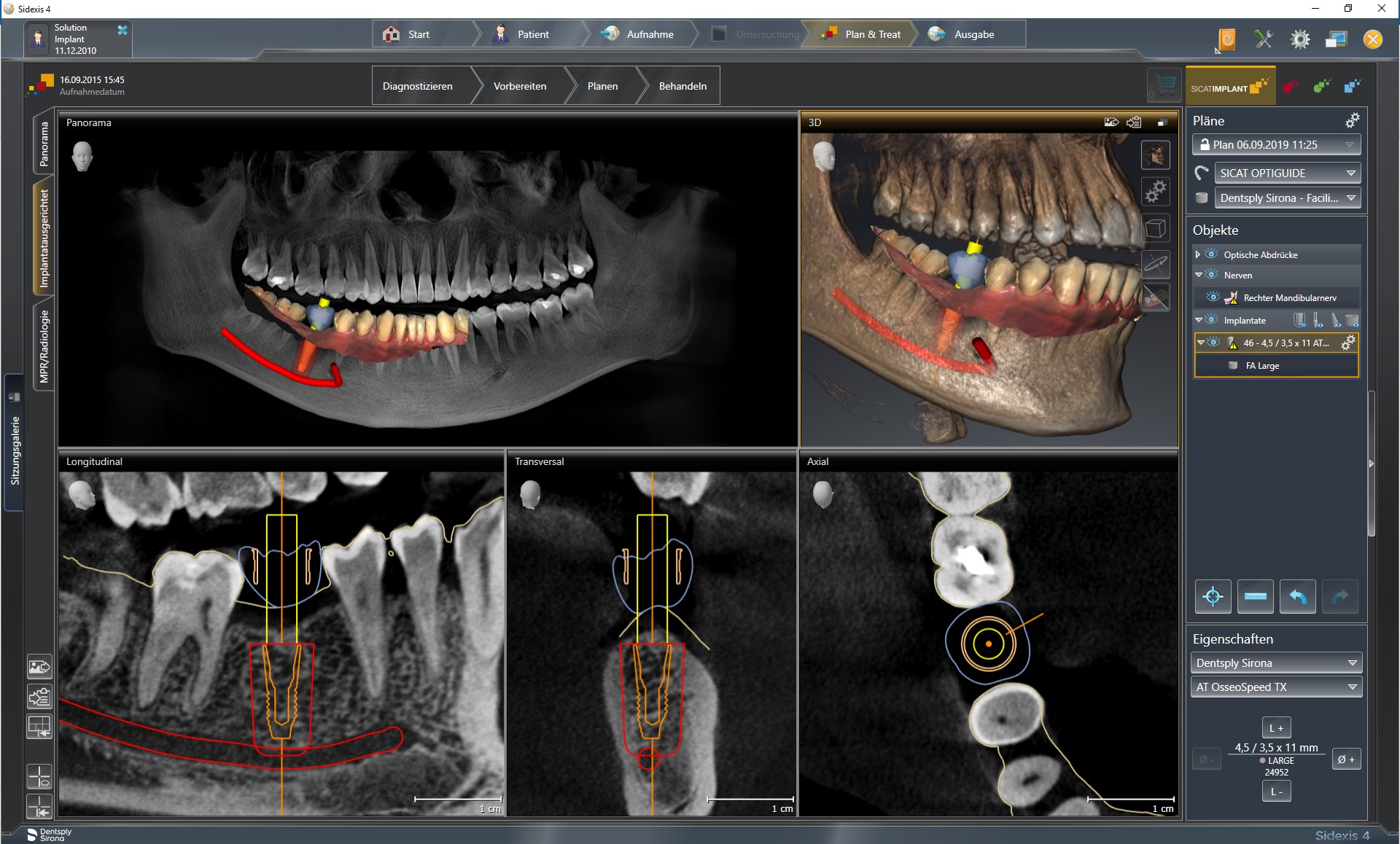

The use of implant software (for diagnostics and digital planning of implants) is a link in the digital processing chain and follows imaging procedures. It can process 2D and 3D X-ray data (from digital orthopantomographs, CTs or CBCTs) as well as clinical data scanned with intraoral scanners and visualise it with integrated viewer programmes. Apart from extremely precise, distortion-free images (including clear alignment of structures by overlapping partial images), aids such as scanbodies of known 3D geometry are also essential for transferring dimensions reliably. The image can be rotated three-dimensionally as required and flat (cross-sections) or curved 2D views calculated. Important structures (such as the mandibular canal) can be coloured in 3D images. Measuring instruments can be faded in for determining distances or angles thus making implant software suitable for preoperative diagnostics (bone volumes, bone quality, arrangement of important anatomical structures).

For backward planning, implant software can be used for achieving prosthetic objectives (e.g. by fading set-ups or wax-ups of the planned prosthetic restoration into the scan) by defining the parameters for implants and bone availability and evaluating whether augmentation is necessary.

Datasets of frequently used implants and abutments from virtual libraries stored in the implant software can be embedded in the optical three-dimensional image. This permits realistic planning of the number, dimensions (length, diameter), positioning and alignment of the implants.

Implant software

Implant software

When implant software is used in conjunction with additional CAD programmes or modules, which include virtual teeth, occlusal surfaces, connectors and other prosthetic elements, the prosthesis can be planned entirely digitally. Together with CAM procedures, preoperative fabrication of (bone, tooth or mucosa supported) drilling templates with sleeves for guiding the drill during navigated implantation, custom abutments, temporary or even definitive superstructures is feasible.

One important demand placed on implant software is import/export compatibility (interfaces) with common data formats (such as Dicom and STL standard open formats). Proprietary systems with in-house formats are either tied to these (isolated applications) or can convert them to other (open) formats. In order to process the large datasets imported/exported by implant software, computer systems must possess sufficiently high data processing capacity and speed.

PROBIEREN SIE ES EINFACH AUS !!!

Von uns erhalten Sie professionelle Unterstützung.

Treten Sie mit uns in Kontakt oder nutzen Sie unser Kontaktformular.

Wort des Tages

| Deutsch | Englisch |

|---|---|

| MK-Krone | metal-ceramic crown, bonded crown, porcelain-fused-to-metal crown, PFM crown, ceramometal crown |

Schwerpunkttext des Monats

Vergrößernde Optik in der Zahntechnik Vergrößernde Optik in der Zahntechnik |